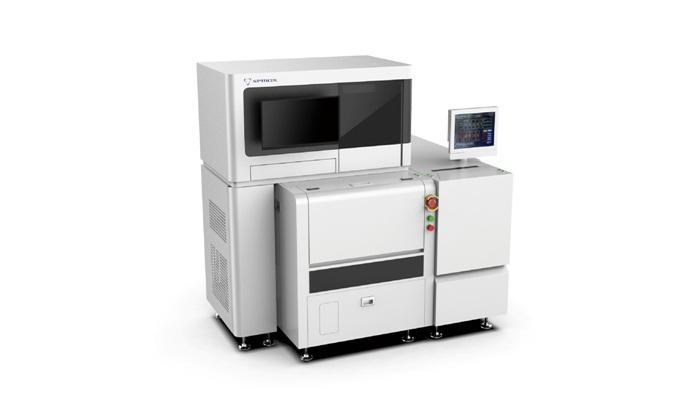

Micro Inspection System

Spirox MA6503D is a high quality image wafer inspection system with features of auto-storing defects image and position coordinate records to replace QC visual inspection on surface defects, including particles, scratches, etc.

FEATURES

FEATURES

Utilize a Line Scan Camera with wide FOV and fast scanning capabilities

Use a 3x lens to enhance image quality and improve the defect characteristics inspection

5μm Defects Inspection Items: Particles, Scratches, Pad Defects, Bump Defects

Support Probe Mark Inspection (PMI) and offer PAD quick selection for detection settings

Support 3D inspection to measurement of Bump height and coplanarity

Auto wafer-level chuck with ±1.7μm accuracy to process high accuracy wafer coordinate alignment

Zoning parameter setting to realize accurate inspection requirement by zones

FUNCTION DESCRIPTION

FUNCTION DESCRIPTION

【Inspection Process】

【Defect Inspection Application】

PRODUCT SPECIFICATIONS

PRODUCT SPECIFICATIONS

| MA6503D | ||

|---|---|---|

| Function |

|

|

| Wafer |

|

|

| Wafer Handling |

|

|

| Chuck |

|

|

| Optical |

|

|

| 2D Image Inspection |

|

|

| 3D Image Inspection |

|

|

| Software |

|

|

| Optional |

|

|